Check out our new waterjet!OMAX 60120 Precision JetMachining Center

EQUIPMENT

Item Description:

- CNC Lathe - Daewoo Lynx 220L - 8" Capability

- CNC Lathes (2) - 0-5" capability Akebono MINC-26 (X6)

- CNC Mill - Hyundai-Kia VX440

- CNC Mill - LK TT510

- CNC Mill- Okuma MC-4VAE 9588

- Automatic Horizontal Bandsaw- Hyd-Mech H-10A 10" x 10" capacity

- Manual Mill - Sharp Knee Mill HMV W/ X&Y Digital readouts

- *NEW* Kent Surface Grinder - 12" X 30"

- Surface Grinder- Sunmax - 8" X 16"

- Horizontal Bandsaw- Jet HVBS-7MW

- Cut-Off Saw- Milwaukee 14" Abrasive cut-off machine

- Air Compressor- Quincy QGS-15

Gauges:

- Mitutoyo Digital dual column height gauge 18" (450 mm)

- Mitutoyo Digital dual column height gauge 12"

- Mitutoyo 0-6 inch Calipers- Dial and Digital - 8 sets

- Starrett Straightedge No. 385

- Gauge Pin 8 Pin Gauge sets

- Gauge Blocks 3 Gauge Block Sets

- Gauge Balls 1 Gauge Ball Set

- Verniers Mitutoyo 0~40 Inches

- Surface Plates Granite Surface Plate with Steel Stand and Wheels

- Browne & Sharpe Quad Cut

- Browne & Sharpe Double Cut

WATER JET

Omax 55100 & 60120

- Precision machining: From prototypes to production runs in sizes up to 6’ x 12’.

- Cuts complex flat parts out of materials including metal, plastic, glass, ceramic and composites directly from a CAD drawing or .DXF file.

- Does not create heat affected zones - No heat-affected zone or thermal damage normally associated with laser or plasma cutters.

TURNING

Our turning centers are designed for long-term high accuracy and superior surface finishes.

Daewoo Lynx

- Bar Capacity: 2.625 " / 66.7 mm

- Axis:2

- Fanuc I CNC Control

- Up to 12" Diameter

- Tailstock, Parts Catcher and Tool Setter

- Spindle Speeds 40 - 4,000 RPM

- X Axis Travel 6.9"

- Z Axis Travel 21.7"

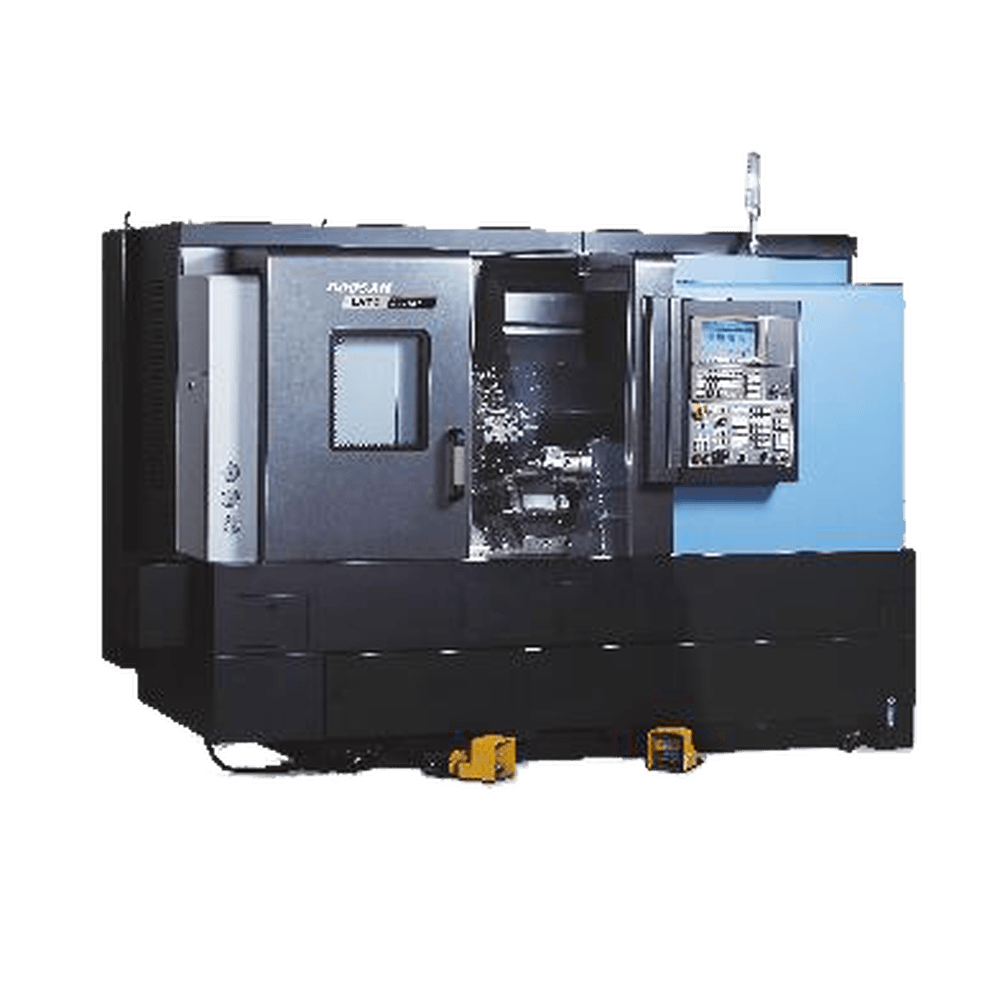

Doosan Lynx 2100SLYB

- Live tool lathe with sub-spindle Y-Axis

- Fast traverse rates minimize non-cutting time

- Bar Capacity: 2.625"/66.7 mm

- Max Turn Diameter: 11.8"

- X-Axis Travel: 8.07"

- Z-Axis Travel: 22"

MILLING

Machining Center accomplished super power heavy-duty cutting with high accuracy, high rigidity, and high precision performance, based on minimized heat

LK

- 3-Axis Vertical Drilling and Tapping Machine w/ Haridinge 4axis indexer.

- The spindle runs in 4 high precision angular contact ball bearings assuring long-term accuracy and maximum rigidity and stability.

- Max Spindle Speed 10000rpm

- Rigid Tapping

- Table Size L:23.600 X W:15.700

- Max. Weight Of Work Piece 550

Hyundai-Kia Vertical Machining

- Table Size Mm(In): 1,000x460(39.4"X18.1")

- Max Load On Table Kg(Lb.): 600(1,323)

- Spindle Speed: 12,000 Rpm

Okuma MC 4 VAE

- 3-Axis Vertical Milling Machine

- X-Axis: 650 Mm Y-Axis: 410 Mm Z Axis: 450 Mm Table Size: 1000x410 Mm

- Maximum Table Load 1,100 Lbs.